Reciprocating saw blades, can cut all can processing of metal, wood, nail with wood, plastic, rubber, composite materials. With special high temperature treatment, high hardness and wear resistance is strong, long service life and can be used for cutting very hard materials. Nail and S644DF Flexible for Metal for Metal cutting wood (5.0-100 mm). Fast linear cutting, aluminum, sheet, with nails, wood profiles (10-100 - mm), 150 mm standard blade length can reach 100 mm cutting ability and is suitable for all type S axis reciprocating saw

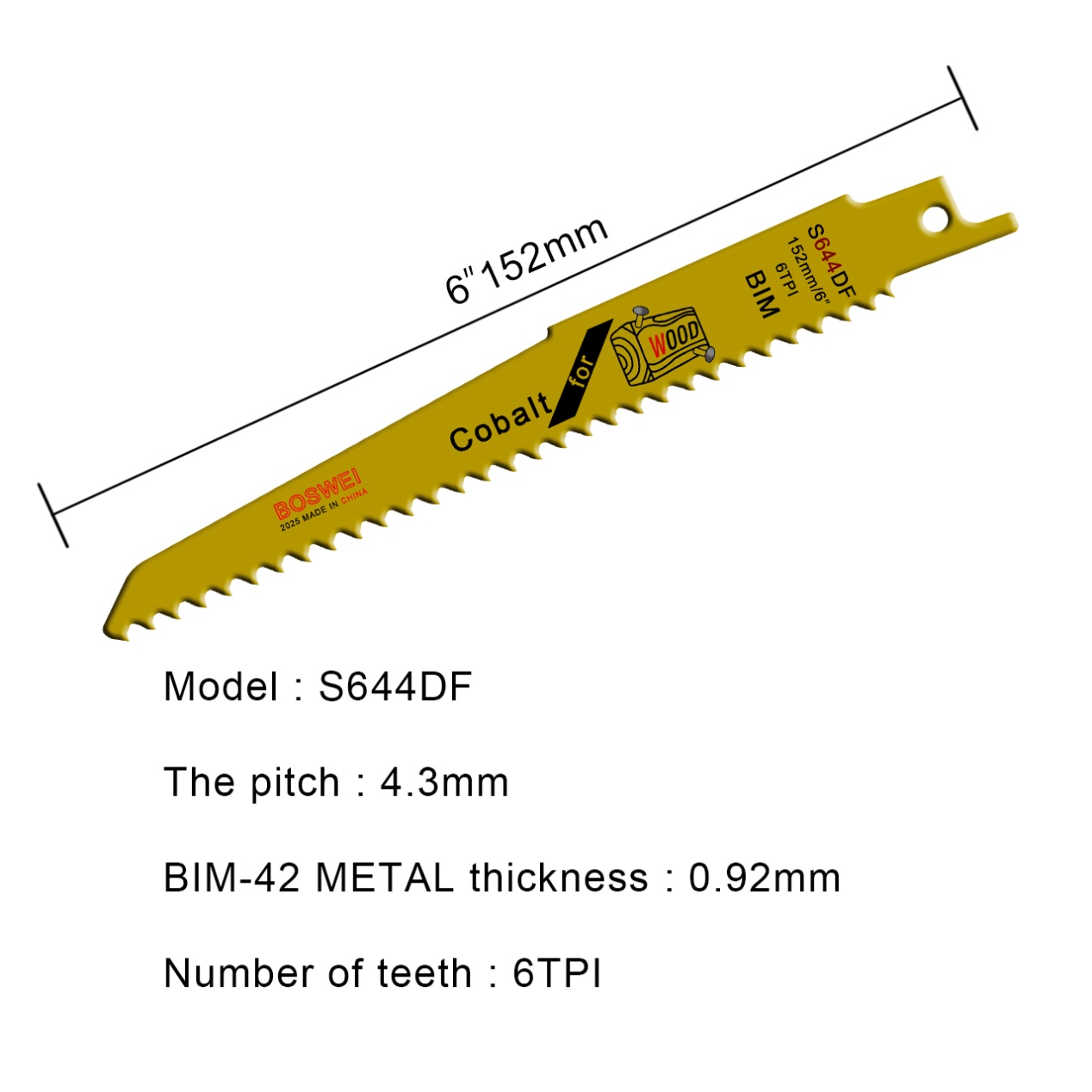

General handle system with 1/2 inch of reciprocating saws are used together. S 644 df for metal reciprocating saws Flexible is optimized for fast cutting metal. It's pitch is specially designed for high speed work. Blades made of BIM (double metal), designed for use in the cutting of normal strength steel has a longer service life. In addition, it also equipped with 4.3 mm pitch, used for cutting thickness is 5 mm to 100 mm of plastic pipes and profiles. The standard length of the reciprocating saw blade is 150 mm, maximum cutting ability is 100 mm.

• fast cutting of small diameter tube and profiles

Reciprocating saw blades, applicable to metal S644DF flexible blade optimized, can quickly cut wood with metal

• pitch is specially designed for high speed machining

• BIM saw blade design service life is long, can be cutting standard strength of steel

• pitch (4.3 mm) is used for cutting plastic pipe/profile (5-100 - mm). Standard blade length (150 mm), can achieve 100 mm cutting ability

Areas of application: with nails/metal boards (5-100 - mm), the entity tubes/profiles (diameter < 100 mm), fast cutting epoxy glass fiber reinforced plastic (GRP)

The metal plate